Underwater welding has began on World War I

(1914-1918) when The British Navy want to repair their ship hull quickly. They

had not sent their ship to docking with this method. At first, this method only

for temporary repairs but soon on as the knowledge gained this method has grow

up in safety and technology aspect.

Hyperbaric Welding

Hyperbaric welding is a underwater welding

method that uses chamber. Hyperbaric welding can be used up to 500m in water

depth.

Hyperbaric welding characteristics

- — Hyperbaric welding involves the weld being performed at the prevailing pressure in a chamber filled with a gas mixture sealed around the structure being welded.

- —Chamber is sealed around the structure that be welded and is filled with the gas (He and Oxygen) at the prevealing pressure

- Most welding processes SMAW, FCAW, GTAW, GMAW, PAW could be operated at hyperbaric pressures, but all suffer as the pressure increases. Gas tungsten arc welding is most commonly used.

Types of hyperbaric welding habitat

- Structurals

- EPRS

- Tie Ins

- Hot Taps

Structurals

Repair to asset, as

result of in service stress/deterioration or accidental

damage. Usually, (but not

limited to), repair upon an offshore platform, tubular lattice work, leg or riser, examples being the repair to compromised weld itself or

installation ofreplacement section of pipe work, whole brace or pup piece.

Source:

subsea7

Tie Ins

“Tie In”, the connection of a sub sea pipe line to a platform (or other structure/asset).

Laydown head of new pipe line, in a deployment window, at set distance from platform riser end, eg, 30 to 50mts.

A variation of this type of arrangement is used for a by pass when decommissioning a platform but

retaining use of existing pipe

line infrastructure.

Source:

subsea7

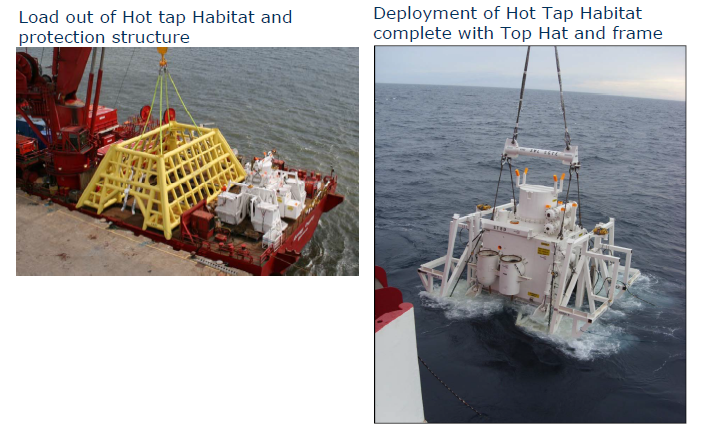

Hot Taps

Technique to allow another pipeline to gain product flow access, to

an existing pipeline, with out the primary pipeline being

shut down. Commonly, pre-heating equipment has been

installed in the chamber.

Source:

subsea7

EPRS (Emergency Pipeline Repair System)

The EPRS is comprised of a Habitat, pipe handling frames, containerised

units consisting of weld control,

workshops, hot water machines, stores, consumables,

hyperbaric pigs, Habitat services, hydraulic and welding umbilical’s, on dedicated winches, compatible

parent pipe sections and other ancillary equipment.

Advantages and

Disadvantages

Advantages

- welder/diver safety

- Good in welding quality

- Surface monitoring

Disadvantages

- Higher cost of process, training, etc.

- Large quantity of costly and complex equipment

- More deep, more energy requirement

- Can’t weld if weld spot is located at unreachable place

- Must adapt to the chamber set-up

Safety

Due to AWS D3.6 Specification for Underwater

Welding, It recommended safe practices for

- safe practice/operation manual

- communication

- electrical equipment

- hand-held power tools

- preparation for work

- performance work

- inception and examination

References

Clenner, A.2008. Subsea

Pipeline Engineering. Penn Well Books.

http://www.slideshare.net/shobhitbytheway/underwater-welding-14810484,

accessed by May 2013.

http://www.nui.no/sitefiles/22/Dykkeseminar/2011/pdf/NUIPresentation-HyperbaricWeldingTodayAnOverview.pdf,

accessed by May 2013.

http://nwhss.org/Program/March11/NEPSYS_Presentation_11-2010.pdf,

, accessed by May 2013.

http://www.metalwebnews.com/howto/underwater-welding/underwater-welding.pdf,

accessed by May 2013.

Tidak ada komentar:

Posting Komentar